Metal Additive Manufacturing Trends for 2023

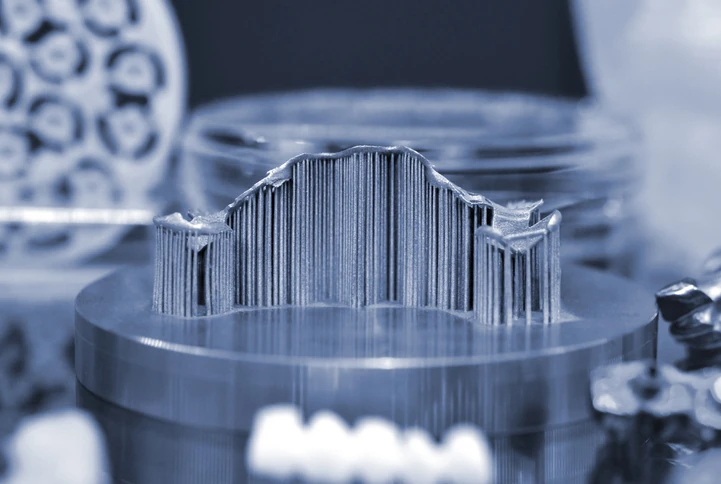

Metal additive manufacturing (MAM) is a process of producing complex 3D figures by adding fine powder layer by layer. From creating custom-finished parts to producing in mass quantities, MAM is changing the manufacturing industry.

MAM technologies are consistently improving existing technology or implementing new machinery – which has led to the manufacturing market adopting MAM as a viable solution, rather than a novelty. In past years, using additive manufacturing (AM) for mass production was an unrealistic dream. Now, metal AM is exploring new technologies, allowing that dream to become a reality with more industries adopting AM practices daily.

In 2023, we should expect to see additive manufacturing trends revolve around the technological advancements of MAM.

3 Metal Additive Manufacturing Trends to Watch in 2023

Metal additive manufacturing technologies have revolutionized the way components and parts are produced. With this ever-evolving industry, 2023 is expected to push the boundaries of AM’s production capabilities.

Three additive manufacturing trends every project manager or engineer should pay attention to this year are:

- Large-scale production

- Upskilling

- Metal post-processing

1. Large-Scale Production

While additive manufacturing has already expanded beyond rapid prototyping, it’s still widely used for that sole purpose. Sculpteo’s 2020 study, “The State of 3D Printing,” found that 50% of companies surveyed already used 3D additive manufacturing technology for production rather than prototyping. In 2023, we expect this number to increase exponentially.

One of the industries taking off in large-scale MAM is the aerospace industry.

NASA is leading the additive manufacturing revolution in the aerospace industry and we expect to see more businesses continue to adopt these processes. In 2022, NASA made incredible strides by developing new alloys with enhanced strength, flexibility, and durability. NASA project managers found that metal additive manufacturing made experimenting with new materials a process that takes weeks or months as opposed to the traditional years-long timeframe.

Resource: Want to learn more about mass production in 3D printing? Check out this article to discover how metal AM can upgrade your manufacturing.

2. Upskilling

With MAM becoming an integral part of manufacturing around the world, OEMs of all sizes should be already taking steps to integrate this process into their operations. This goes beyond purchasing equipment. Rather, it’s about educating employees in this production methodology.

In 2023, we expect to see continued growth in demand for virtual education courses designed with AM professionals in mind.

While adding a new process to an existing operation – regardless of size – is never a small task, investing in both the equipment and, more importantly, employee training is something that will pay long-term dividends.

3. Metal Post-Processing

Post-processing is essential when it comes to additive manufacturing. As the last step in production, components receive finishing touches to improve design and properties while ensuring accuracy.

In the past, post-processing was viewed as labor-intensive, costly, and inefficient. Frankly, it was. Parts were polished piece-by-piece, resulting in inconsistent finishes. Post-processing was overlooked, no one wanted to spend the time or money on it.

Now, with automation, post-processing has improved and is becoming a critical part of MAM’s future.

With this upgrade, post-print finishing doesn’t bottleneck production as it once did, freeing technicians to focus their time elsewhere.

Metal additive manufacturing post-processing has always been an essential step in production across a host of industries from automotive to medical. During 2023 (and beyond), we anticipate automation and technological improvements to continue making it a more straightforward process.

How is MAM Used Today?

Automation is changing the way we live – and additive manufacturing trends are following suit. Companies around the world are using this technology to streamline production with 3d printers that require minimal intervention and oversight.

Unlike traditional manufacturing, MAM offers a hands-off approach. With a (nearly) set-it-and-forget-it production strategy, manufacturing is becoming a whole new world. Instead of having employees sit behind a machine all day, someone will walk in, check that the machines are up and running, and leave.

From limiting work accidents to reducing operational costs for manufacturers, the benefits of next-gen manufacturing are almost endless. Years ago, hands-off manufacturing would have been unimaginable, but with the additive manufacturing trends forecasted for 2023, it’s not too far-fetched anymore.

Is MAM the Solution for You?

Knowing where to begin when implementing metal additive manufacturing methods can be difficult. Let our team help you get started with the future of manufacturing today.