Metal Injection Molding: Producing Complex Geometries & Unique Components

Metal injection molding (MIM) combines the best characteristics of plastic injection molding and powder metallurgy to produce superior metal components with versatile mechanical and magnetic properties. During the process, finely powdered metal is mixed with binder to create a feedstock, which is then shaped and solidified into its final form.

The MIM process is ideal for producing medium and high-volume components with tight tolerances and unique geometries. Freedom of design and flexibility in material choice has made it perfect for several industries.

Metal Injection Molding Markets Served

Medical & Dental

It’s hard to find another manufacturing technology (other than MIM) that can use the ultra-specific materials the medical and dental industries use, making MIM a perfect fit to serve the medical industry.

The broad spectrum of materials that can be processed, from stainless steels through super-alloys, combined with intricate shaping capabilities and fully dense part matrices provide cost-effective solutions to incredibly demanding component requirements.

We're currently committed to and working on obtaining a Medical Device certification (ISO 13485) to further serve this industry.

Aerospace & Aviation

Superalloys and other new MIM materials are being developed every day, providing exciting new options for aerospace design engineers.

The inherent cost advantages of MIM, coupled with the ability to produce highly complex shapes, makes it a preferred choice over competing metal-forming technologies.

Once thought only as a source for engine components, MIM products are now commonly found in doors, seats, and table tray mechanisms.

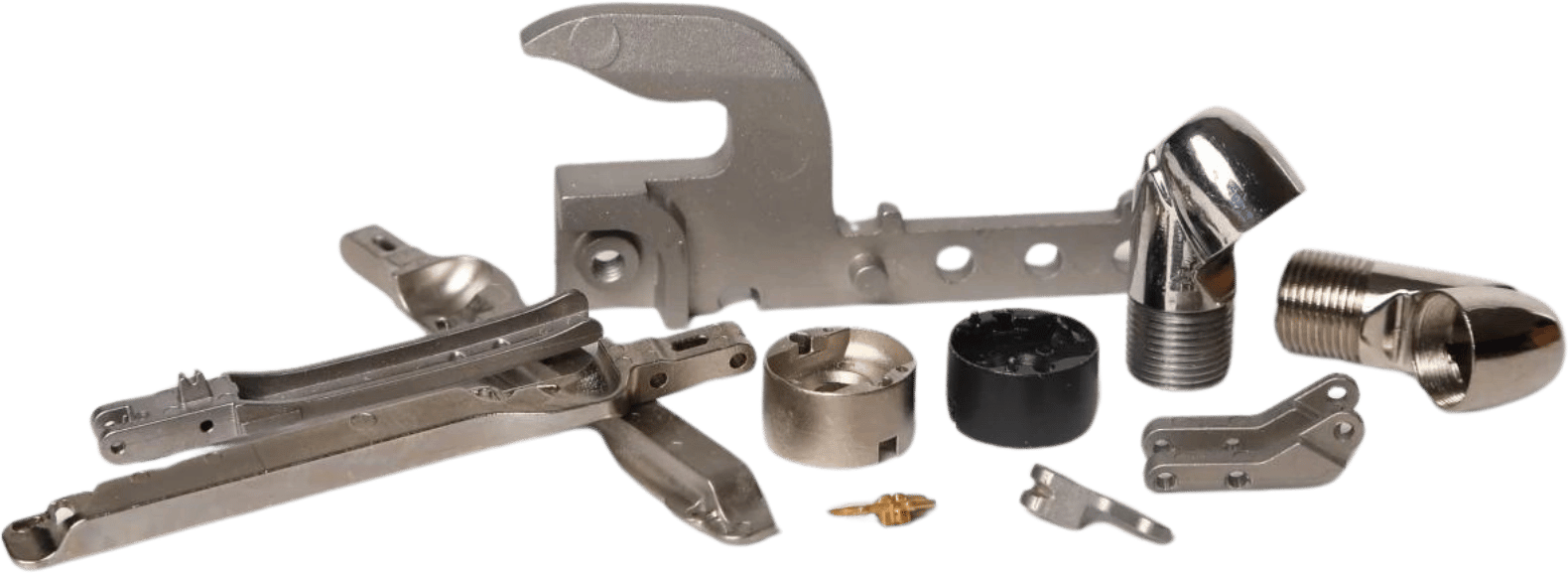

Consumer & Industrial

MIM technology can be found in many of the products we encounter in our everyday lives.

Hand tools, power tools, small electric motors, eyeglasses, locks, and lock mechanisms are just a few examples where MIM components are prevalent.

The capability to provide high production volumes at a lower relative cost has made MIM a preferred technology solution for consumer and industrial markets.

MIM’s fundamental advantage - the ability to provide near full density complex shapes while practically eliminating the need for secondary machining operations – allows customers of MIM technology to optimize their product designs for both utility and cost.

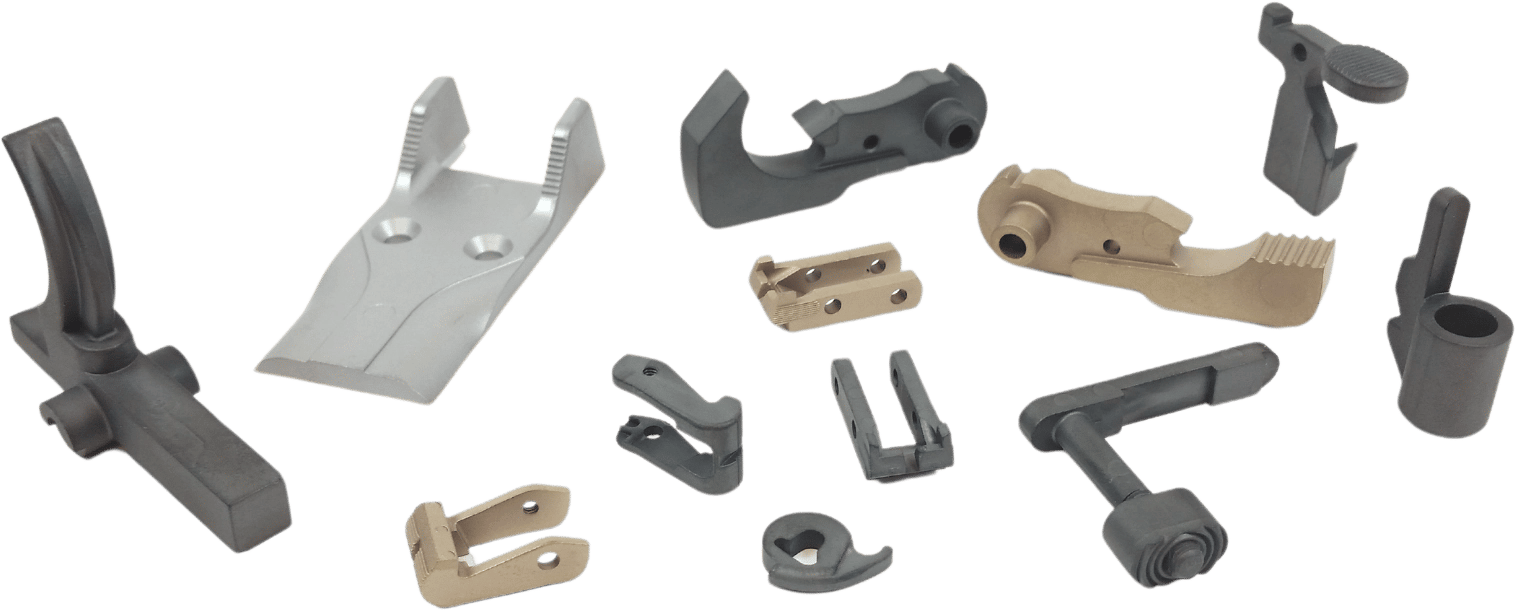

Firearms

The firearms industry has been relying on MIM technology for years. Nowadays, there are several components made almost exclusively using MIM technology:

- Trigger mechanisms

- Triggers

- Frames

- Slides

Why Choose Metal Injection Molding?

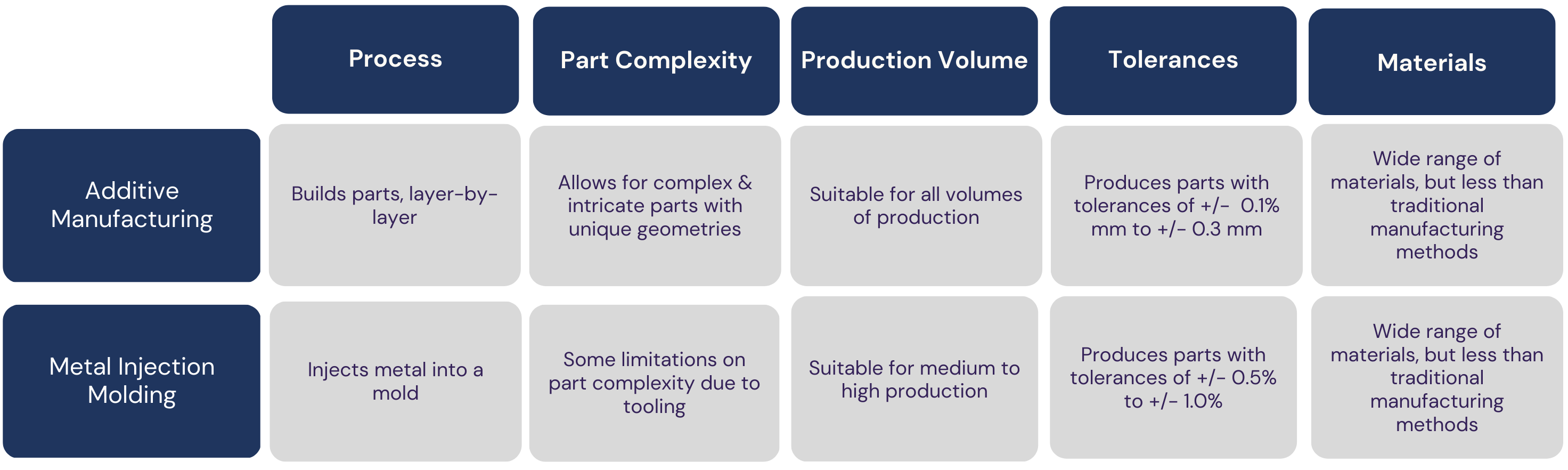

The metal injection molding (MIM) process stands out for its wide material selection and four key benefits when compared to other methods:

1. Complex Geometries

MIM allows for the production of parts with intricate designs similar to those made through plastic injection, including detailed internal structures and thin walls. This capability is enhanced by tight tolerances for optimal fit and function.

2. Cost-Effectiveness

MIM is cost-efficient due to its automation, which reduces labor costs, and minimal waste production, lowering material costs. The precision of MIM minimizes the need for secondary finishing and assembly, further saving expenses.

3. Consistent Quality

The automated and repeatable nature of MIM ensures uniform quality across parts. High-quality metal powders and a controlled environment reduce variability and defects, maintaining consistent part quality.

4. Density & Strength

High-density MIM parts possess superior mechanical properties, such as strength and durability, ideal for components exposed to high stress and wear.

Metal Injection Molding Materials & Properties

Our MIM material specialists can help you select the best materials for your project’s specific needs. Already have one in mind? No problem! Take a look at our list of materials below to see their specifications:

Get Started with a MIM Process Today

Metal injection molding technology allows for design freedom and material flexibility. Think it might be a fit for your next project? Let's find out!