Metal Additive Manufacturing: The Engineer's Guide

In this guide, we’ll explore the ins and outs of metal additive manufacturing, including the steps of the process itself, types of additive technologies, and how it can reduce manufacturing costs and time-to-market.

Open A World of Possibilities with Metal Additive Manufacturing

.jpg?width=531&height=376&name=iStock-1397149632%20(1).jpg)

Are you tired of the limitations of traditional manufacturing methods? Does the idea of creating custom, intricate metal parts quickly and efficiently make your heart race? If so, then metal additive manufacturing (also known as metal AM, MAM, or metal 3D printing) is here to revolutionize your world!

Imagine the possibilities as metal AM catapults your business into new realms of productivity, transforming industries like aerospace, automotive, healthcare, and consumer goods. This cutting-edge technology enables you to create custom-made, one-of-a-kind parts while slashing material waste, production costs, and lead time

With metal AM, you can fabricate lightweight, high-strength components that were once thought to be too complex or downright impossible to produce.

Let’s take a deeper dive into the world of metal additive manufacturing and what it can bring to your business.

What is Metal Additive Manufacturing?

Metal additive manufacturing employs specialized equipment to create custom 3D-printed metal components with high precision and accuracy. This innovative technique constructs geometrically intricate shapes from computer-generated frameworks (CAD models) using a layer-by-layer approach. Depending on the MAM technology, successive layers of metal powder or molten metal droplets are melted and solidified by laser or electron beams to achieve the desired geometry based on the initial computer design model.

Once all layers are deposited, the part undergoes post-processing, which includes quality control checks and finishing operations, such as polishing, sandblasting, and additional heat treatments before it’s ready for use.

How Does Metal Additive Manufacturing Work?

Metal additive manufacturing employs specialized equipment to create custom 3D-printed metal components with high precision and accuracy. This innovative technique constructs geometrically intricate shapes from computer-generated frameworks (CAD models) using a layer-by-layer approach. Depending on the MAM technology, successive layers of metal powder or molten metal droplets are melted and solidified by laser or electron beams to achieve the desired geometry based on the initial computer design model.

Once all layers are deposited, the part undergoes post-processing, which includes quality control checks and finishing operations, such as polishing, sandblasting, and additional heat treatments before it’s ready for use.

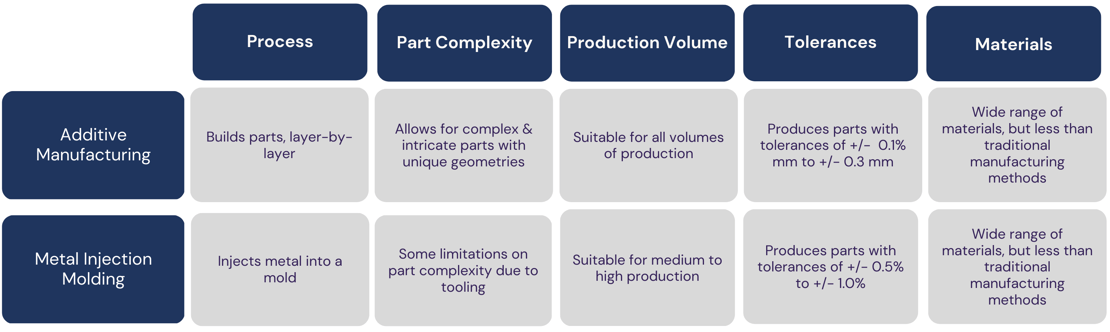

Now that we’ve given you a brief definition of what metal AM is, we can further break down the individual steps of the metal additive manufacturing process, which include:

- Design 3D Model Using Computer Aided Design

- STL File Creation & File Manipulation

- Machine Setup

- Building Layer-by-Layer

- Part Removal

- Post-Processing

1. Design 3D Model Using Computer-Aided Design (CAD)

The first step in the additive manufacturing process is designing a digital 3D model of your part. The most common way to achieve this is through CAD software, though some metal additive manufacturing companies use reverse engineering to create models via 3D object scanners.

Regardless of which tools you use, you’re creating a replica of the 3D model, so it’s crucial to ensure every detail is precise and modeled to the right shape and size.

2. STL File Creation & File Manipulation

Next, the CAD file is converted into another format, such as standard tessellation language (STL) or an additive manufacturing file (AMF).

These formats capture all surfaces of the model by stitching triangles of various sizes on its surface. The main difference is that AMF can support color, materials, lattices, and castellations. STL only supports the surface geometry of the object.

The file is then imported into a slicer program that converts it to G-code, which tells the printer what to do and how to do it according to your parameters.

3. Machine Setup

The setup process for MAM varies depending on which technology you use. Variables include:

- Model orientation - The positioning of the 3D model within the build volume of the printer.

- Material selection - When choosing the material for your part, it’s essential to consider its end-use and desired properties.

- Printer temperature - Temperature directly affects the quality, strength, and integrity of additive parts.

- Support structures - Any material used to provide structural support to an overhanging or otherwise unsupported portion of a printed part during the build process.

- Build platform leveling - Ensuring the print bed or build surface is flat and aligned with the print head or deposition system.

- And more

During this step, print material, binders, and other consumables are loaded into the machine. The raw materials require careful handling and often have a limited shelf life.

Note: Additive manufacturing machines consist of many small and intricate parts, so operators must maintain and calibrate them regularly to produce accurate prints.

4. Building Layer by Layer

The printer gradually builds the model by depositing one layer at a time. Depending on the process selected, this step can be a few hours up to days. Build time is dictated by:

- Build size

- Additive manufacturing technology

- Printing resolution

Most metal AM machines don’t need oversight after the print starts. This allows the technology to be used as a “lights out” operation.

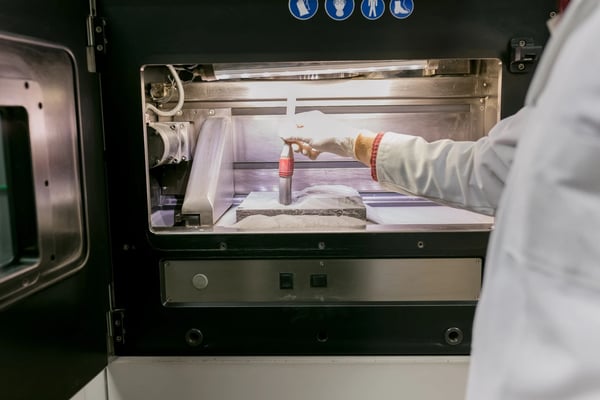

5. Part Removal

Sometimes removing a print is as simple as separating the part from the build platform and support structure.

However, some industrial 3D printing methods require a more refined process involving extraction of the print while it’s still attached to the build plate or encased in build material. In these situations, a highly skilled machine technician with proper safety equipment is a must.

6. Post-Processing

Post-processing varies depending on the printer technology and materials used.

For example:

- Metal parts may need to be stress-relieved in an oven.

- Parts produced with stereolithography (SLA) technology must be cured under UV light before handling.

- Prints created through fused deposition modeling (FDM) can be handled immediately.

- Support structures may need to be removed.

Advantages & Disadvantages of Metal AM

Metal AM offers a wide range of benefits, such as:

- Reduced material waste

- Faster prototyping & Iterating

- The ability to create parts with complex geometries

However, as with any manufacturing process, there are also potential disadvantages to consider, including the high cost of equipment, post-processing requirements, and material limitations.

Advantages of Metal Additive Manufacturing

-1.png?width=1140&height=374&name=Additive%20Manufacturing%20vs%20Traditional%20Chart%20(1)-1.png)

From the consolidation of assemblies to rapid prototyping and decreased energy consumption, metal additive manufacturing has a lot to offer your production:

- The consolidation of assemblies into a single part

- The ability to improve existing part properties

- Creating lightweight parts and assemblies

- Unrivaled parts customization

- Rapid prototyping and iteration of parts and assemblies

- Waste reduction

- Inventory stock reduction

- Decreasing energy consumption

- Being an ideal choice for producing high or low volumes of parts

- Allowing for distributed manufacturing

1. Ability to Consolidate Assemblies Into a Single Part

In many industries, parts are assembled into larger subassemblies or modules, which are then integrated into larger assemblies. This approach can be time-consuming due to assembly time and labor, lead to an increase in the number of potential failure points, and often results in high levels of scrap and waste.

Additive manufacturing offers a solution to these problems by allowing assemblies to be consolidated into a single part. This eliminates the need for assembly altogether, potentially reducing cost and waste while increasing efficiency.

2. Improve Existing Part Properties

Compared to their conventionally assembled counterparts, additively manufactured parts have been found to have superior mechanical properties. This is due, in part, to the microstructural features that can be achieved with AM.

For example, Selective Laser Melting (SLM) can be used to create fine, uniform microstructures with high aspect ratios that are not possible in conventional casting or machining processes. As a result, SLM can potentially improve the mechanical properties of existing parts by increasing strength and ductility while reducing weight..

3. Ability to Create Lightweight Parts

Not only does AM allow for the creation of parts with intricate designs, but also parts that are lighter weight This is because AM parts can be designed with hollow spaces and other internal structures that reduce the overall weight of the part without sacrificing strength or durability.

Lighter-weight components mean:

- Reduced shipping costs

- Lower fuel consumption

- Reduced wear and tear on machinery

4. Unmatched Customization

Unlike traditional manufacturing methods, which require the use of standard molds and dies, AM creates objects with unique shapes and dimensions with minimal upfront investment.

Additive manufacturing technology is also great for creating small batches of customized parts or products, making it an ideal solution for businesses that require high levels of customization.

5. Rapid Prototyping & Iteration.webp?width=523&height=294&name=iStock-1167549708%20(1).webp)

In the past, developing a new product could take months or even years. With MAM, you can create a prototype in days or weeks, without the need for expensive tooling or complex assembly processes. Rapid prototyping allows you to quickly and easily create prototypes. This saves both time and money in new product development.

6. Waste Reduction

Unlike traditional manufacturing methods, such as milling or casting, which often involve cutting away excess material or producing material waste during the process, metal AM allows for near-net shape production with minimal material loss. Most unused material can be recycled and reused, further reducing waste.

7. Inventory Stock Reduction

With traditional manufacturing methods, businesses must keep a certain amount of parts on hand in case of emergency repairs or unexpected customer demand. Additive manufacturing changes this model, allowing businesses to produce parts on demand, as needed. As a bonus, this reduces the amount of money tied up in inventory.

8. Lower Energy Consumption

Additive manufacturing is a game-changer in reducing energy costs. The AM process generally uses less energy than traditional manufacturing processes such as machining or injection molding.

How?

- Additive manufacturing allows for the production of lightweight parts that require less material, both of which result in lower energy consumption.

- Metal AM can be performed using locally sourced materials, which reduces the need for transportation.

- Additive manufacturing generates very little waste and excess material can be reused.

9. Great for High or Low-Volume Productions

For years, AM technologies have been widely used for the low-volume production of customized products. The introduction of multi-material capabilities and the development of faster print speeds make additive manufacturing an excellent option for mass production.

10. Distributed Manufacturing

Metal AM opens the doors to distributed manufacturing, or to the decentralized production of goods, using a network of small-scale printers.

This approach has several advantages over traditional manufacturing methods, in that AM:

- Allows products to be manufactured closer to the point of need, reducing transportation costs and lead times.

- Gives designers greater flexibility to customize products for specific users or applications.

- Can help solve supply chain problems, as additive materials are widely available and you can manufacture the number of parts you need, right when you need them.

Disadvantages of Metal AM

In addition to the numerous key benefits of additive manufacturing, the technology also presents potential disadvantages, including:

- Initial start-up cost

- Post-processing requirements

- Material limitations

1. Initial Start-Up Cost

One of the main barriers holding up the widespread adoption of additive manufacturing is the high cost of entry.

3D printers and associated software can be very expensive, especially for small businesses and hobbyists. And that’s not to mention other costs such as the price of materials.

Working with a manufacturer with established metal AM technologies lets you capitalize on the benefits of the process, without financing the startup costs.

2. Post-Processing Requirements

After a part is printed using additive manufacturing, there are often additional steps needed to prepare it for use.

Post-processing adds additional time and cost to the overall manufacturing process. In some cases, post-processing can actually be more expensive than the printing itself. In addition, post-processing can be complex and time-consuming, requiring specialized skills and equipment.

3. Material Limitations

While the list of materials that can be used for AM is rapidly growing, it remains smaller than what’s available for traditional manufacturing methods. This can limit the range of products that can be manufactured using AM, depending on your part requirements.

Exploring Different Metal AM Technologies

Additive manufacturing is a multifaceted field, with each technique offering its own set of pros and cons. The method you choose will depend on a variety of factors, including part size, materials, and desired properties.

Let’s take a closer look at each:

• Binder jetting• Material jetting

• Powder bed fusion

• Material extrusion

• Vat photopolymerization

• Sheet lamination

• Directed energy deposition

Binder Jetting

The binder jetting process uses only two materials: a binder and a powder-based material (typically metal).

The binder (usually a liquid) is an adhesive between the layers of powder. A print head moves horizontally along the X and Y axes of the machine, depositing layers on the build platform and binding the material.

Material Jetting

The material jetting process is similar to how your 2D inkjet printer operates. Using a continuous or drop-on-demand (DOD) method, the material is jetted onto the platform where it solidifies and takes on another layer.

Powder Bed Fusion

Powder bed fusion uses lasers or electron beams to melt and fuse different powder materials.

This process employs several printing techniques, such as:

- Electron beam melting (EBM)

- Selective laser sintering (SLS)

- Selective laser melting (SLM)

- Selective heat sintering (SHS)

- Direct metal laser sintering (DMLS).

Material Extrusion

Material extrusion is one of the simplest additive manufacturing technologies to understand. Material is drawn through a nozzle, heated, and deposited onto the platform layer-by-layer. The nozzle moves horizontally while the platform moves up and down as each layer is deposited.

Vat Photopolymerization

The vat photopolymerization process uses a tub of photopolymer resin to build its objects layer-by-layer. Afterward, an ultraviolet (UV) light hardens the resin where necessary.

Unlike powder-based methods, no structural support is made from the material to stabilize the object being made. The operator must add support structures manually.

Sheet Lamination

The sheet lamination process includes two types of manufacturing:

UAM uses sheets of metal bound together by ultrasonic welding. LOM uses a similar layer-by-layer tactic but uses paper as the primary material and adhesive instead of metal and welding, respectively.

Directed Energy Deposition

Directed energy deposition (DED) is a much more complex process, typically used to repair or add onto an existing component. It spans several different manufacturing processes and typically costs more than other additive manufacturing types.

MAM FAQs

We understand that this rapidly evolving technology can generate numerous questions and concerns - to help address some of these, we’ve compiled several of the most frequently asked questions about metal additive manufacturing:

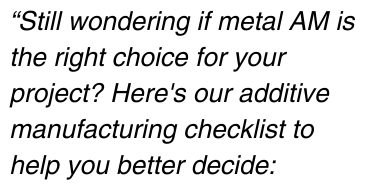

Is Metal Injection Molding the Same As Metal AM?

Below is a quick overview of the main differences between these two technologies:

Is Metal Additive Manufacturing Expensive?

Although the initial investments in machinery and software are expensive, the actual metal additive manufacturing process is not. This is why many OEM sellers outsource their metal AM needs.

Most metal AM projects cost less because of the reduced amount of scrap waste produced. This, combined with fast turnaround times and intricate quality, makes metal additive manufacturing one of the most cost-effective and successful production methods.

Additive manufacturing technology gives engineers design freedom that’s not available using traditional manufacturing methods. This is another way for innovative companies to achieve cost savings while maintaining design freedom and product innovation.

For example, consolidating an assembly into fewer component parts provides an opportunity to reduce assembly time and component costs. By reducing part count, fewer fasteners are needed, fewer subcomponents need to be ordered and tracked, and there’s less chance for assembly error. Operation steps are also reduced, lowering the number of tools, operators, and manufacturing equipment needed.

Metal Additive Manufacturing Materials

Engineers can use many different materials in the metal additive manufacturing process. Though the list isn’t as extensive as other manufacturing methods, there’s still a wide array of metals compatible with metal 3d printing.

From lightweight and high-strength titanium and aluminum alloys to corrosion-resistant stainless steels and heat-resistant nickel-based alloys, below is a preview of materials compatible with the metal additive manufacturing process:

| Titanium | Stainless Steel | Aluminum |

|

|

|

| Nickel-based Alloys | Cobalt-Chromium Alloys | Tool Steels |

|

|

|

Material compatibility depends on the type of AM technology used (and new options are constantly being added!), so make sure to work closely with a dedicated metal additive manufacturer before deciding on a process and materials.

Finishing Options for Metal Additively Manufactured Parts

Based on their intended application, certain metal additive components may require a surface finishing procedure before they can adequately fulfill their designated purpose. Common reasons for finishing these parts may include:

- Enhancing appearance

- Improving durability by increasing resistance to wear, heat, corrosion, etc.

- Adjusting shape and size

- Smoothing out uneven surfaces

- Boosting electrical conductivity

Although the inclination to select a metal additive manufacturing method first and address post-processing later might be strong, it’s essential to consider the surface finishing approach during the design phase. Evaluating the distinct characteristics of your component is crucial, as the chosen finishing technique can influence these attributes, such as:

- Shape, material, thickness, and weight

- Intended function

- Performance in harsh environments

10 Surfacing Finishing Techniques of Metal Additive ManufacturingHaving explored the primary motivations behind finishing metal additive components, let’s delve into an overview of ten commonly used surface finishing techniques that can enhance your part’s functionality and performance: 1. Media BlastingHere, compressed air is used to propel a blast media, such as sand, stainless steel shot, or glass beads, against the part to reduce surface roughness. This process is useful in removing surface imperfections. 2. Shot PeeningShot peening is similar to media blasting, but with a different goal in mind. Instead of removing imperfections from the surface of your object, this process is used to increase its strength and durability. During shot peening, pressurized air shoots metal or plastic beads at a surface, causing changes in the mechanical properties of the surface (i.e. resistance to wear). 3. Green SandingThis is useful for reducing the appearance of printed layer lines and other imperfections. Green parts are relatively soft before sintering, so you can smooth out imperfections with a scouring pad or sandpaper before sintering. 4. Tumble FinishingDuring tumble finishing, your parts are placed in a barrel along with water, an abrasive media, and a compounding agent. The rotation of the barrel causes everything to tumble down upon itself, causing friction and abrading the parts. This process works well with large or small parts, though it’s best-suited for parts with simple geometries. Tumble finishing parts with complex geometries can lead to non-uniform finishes. 5. Vibratory FinishingSimilar to tumble finishing, vibratory finishing is another solution for finishing a large number of parts simultaneously. During this process, your parts, media, and compounds are placed into a vibratory tub or bowl. The vibratory action causes media and parts to grind against one another, deburring and/or polishing them. The process can be wet or dry, and very gentle or aggressive, depending on your desired surface qualities. 6. Abrasive Flow MachiningDuring this type of internal surface finishing, a viscous, abrasive material is forced through the part, smoothing burrs, polishing surfaces, and removing metal. This type of additive manufacturing finishing uses a hydraulic ram to drive media through your part, creating a “slug” of abrasive material that molds itself to the part. 7. Electrochemical PolishingAn alternative to abrasive polishing, electrochemical polishing uses a chemical etchant stimulated by an electrical current to smooth and treat the internal and external surfaces of a part. This process is inexpensive, though the etchant and waste products must be handled and disposed of properly. 8. Wire BrushingThis involves using a handheld brush, drill, or grinder for deburring, edge blending, and removing surface imperfections. 9. Heat TreatmentsSimilar to shot peening, heat treatments strengthen your parts by reducing tensile pressure. Heat treatments can also be used to increase density or help form parts into your final, desired shape. 10. Traditional MachiningMetal additive manufacturing post-processing can include traditional methods associated with subtractive manufacturing, such as milling and grinding. These operations come into play when your manufacturer needs to further remove material to meet tolerance and surface specs. |

How Does Metal AM Shorten Time to Market?

Metal AM offers increased flexibility of design, waste reduction, and cost-effectiveness – but did you know that it can also shorten time to market?

Let’s look at how:

Product Development Acceleration

Using metal additive manufacturing enables a seamless transition from a CAD file to a functional prototype, often in under a week, depending on factors such as size and the specific AM technology employed. You can easily manipulate the design as needed and reprint, unlike traditional PM, where you may need additional tooling/molds, which takes time.

On-Demand Customization

With metal AM, you can think of a design tod ay and print it by tomorrow, so to speak. Not only can you think of one design, but you can also vet out multiple designs in one build box.

ay and print it by tomorrow, so to speak. Not only can you think of one design, but you can also vet out multiple designs in one build box.

This is especially useful in the medical industry with patient-specific medical devices. Some jewelry designers are even using additive technology to create custom pieces.

Test Parts Before Full Production

Imagine you’re a medical device manufacturer and your customer has a design idea they’d like to test out. You could either use a different metal manufacturing process – which may take weeks or months to come to fruition – or you could leverage MAM as a bridge to production.

Rapid prototyping with metal AM allows you to quickly print a limited production run of parts that clients can touch, feel, and fire. This way, changes can easily be made, if desired, without adding a significant amount of time to the conceptualization process.

Hybrid Additive Manufacturing

MAM and traditional manufacturing processes don’t necessarily have to compete. In fact, they can work together to create complex, lightweight components, with excellent surface finish.

Hybrid additive manufacturing combines both additive and subtractive processes to create the desired component. Combining the two methods may be beneficial in instances where the main benefits of MAM are desired, though a smoother surface finish is needed. In these instances, hybrid manufacturing could combine the speed, efficiency, and freedom of design of metal AM along with the surface control of CNC machining.

Unleash the Possibilities with Metal AM

Metal additive manufacturing has opened up new possibilities in the manufacturing industry, enabling the production of complex and customized parts that were previously impossible or cost-prohibitive. With MAM, you can achieve greater design freedom, reduced lead times, and increased efficiency in your manufacturing processes.

Moreover, the adoption of MAM is expanding rapidly across various industries, from aerospace and defense to medical and dental, automotive, and jewelry. As industry professionals become more familiar with the advantages and limitations of metal AM, we will continue to see new innovations, such as new materials and alloys, improved surface finishes, and increased precision and accuracy. With these advances, metal AM will continue to transform the manufacturing landscape, enabling businesses to stay competitive and meet the demands of an ever-changing market.

In a hurry but still want to read?

In a hurry but still want to read?