What Is Metal Additive Manufacturing? A Comprehensive Guide

Metal additive manufacturing, or metal 3D printing is the process of making a three-dimensional, solid object of nearly any shape or design from a computer-generated framework. The 3D metal objects are often (though not always) created by layering fine metal powders layer-by-layer with a bonding agent used between layers.

How does additive manufacturing work, and how does your industry fit in?

Metal AM is opening doors of opportunity for complex component design, in a growing number of markets, with a widening range of order volumes.

|

|

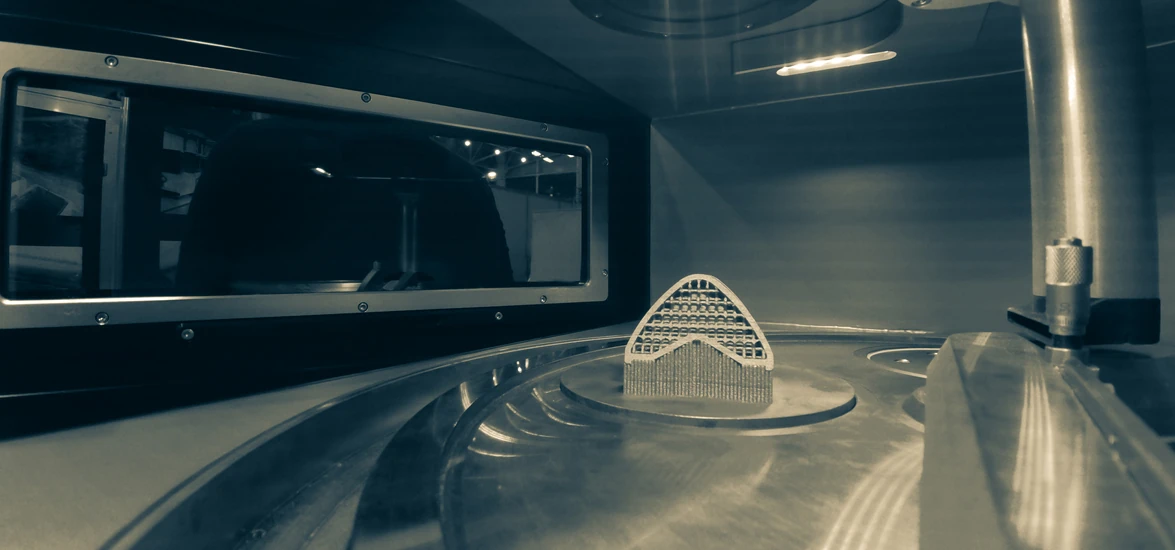

How Does Metal Additive Manufacturing Work?

Metal additive manufacturing is a process that uses fine, metal powders to create strong, complex components that are designed either by using a computer-aided design (CAD) program or by taking a 3D scan of the object.

First, computer software slices the design into many layers that act as the framework for the additive manufacturing machine to follow.

Then, once the design and framework are generated, they're sent to the machine to begin printing, though the exact printing process will vary depending on the machine being used.

The ability to create 3D objects of virtually any shape is what sets additive manufacturing apart from other manufacturing processes like metal injection molding.

8 Types of Additive Manufacturing Technologies

There are many types of additive manufacturing, and each comes with its own advantages and disadvantages.

Common types of additive manufacturing include:

- Binder jetting

- MoldJet technology

- Material jetting

- Powder bed fusion

- Material extrusion

- Vat photopolymerization

- Sheet lamination

- Directed energy deposition

1. Binder Jetting

The binder jetting process only uses two materials: a binder and a powder-based material (typically metal).

The binder (usually a liquid) serves as an adhesive between the layers of powder. A print head moves horizontally along the x and y axes of the machine, depositing layers on the build platform and binding the material.

Here is a simplified, step-by-step look at the binder jetting process:

- The powder material is spread across the build platform

- The print head layers the binder adhesive on top of the powder

- The build platform is lowered

- Another layer of powder is applied to the previous layer, resulting in an object being formed where the powder and liquid are bound

- Any unbound powder stays put, surrounding the object

- The process repeats until the desired shape is finished

2. MoldJet Technology

MoldJet is one of the newest technologies created by Tritone. It’s a sinter-based additive manufacturing process that combines metal injection molding with 3D printing.

Here’s a high-level overview of the MoldJet process:

- The MoldJet Technology works layer-by-layer to fill the newly created 3D-printed mold.

- It creates the first layer by depositing the material where needed, then moves to the second layer.

- Once the mold is filled, the molded material is heated and removed before being sintered in a furnace.

3. Material Jetting

The material jetting process is somewhat similar to how a 2D inkjet printer operates. Using a continuous or drop-on-demand (DOD) method, the material is jetted onto the platform where it then solidifies and takes on another layer.

Here’s a step-by-step of the material jetting process:

- The print head is positioned above the platform

- Droplets of material are jetted from the print head onto the platform

- The material droplets solidify, forming the first layer

- Further layers are added using the same process

- Once the object is complete, post-processing removes any support material formed during the process

4. Powder Bed Fusion

The powder bed fusion process typically includes several printing techniques, such as electron beam melting (EBM), selective laser sintering (SLS), selective laser melting (SLM), selective heat sintering (SHS), and direct metal laser sintering (DMLS).

Ultimately, powder bed fusion uses lasers or electron beams to melt and fuse different powder materials.

Here is a simplified, step-by-step look at the powder bed fusion process:

- A layer of the chosen material is spread over the platform (typically around 0.1 mm thick)

- A laser or electron beam fuses the first layer or cross-section of the model

- A new layer of material is spread across the previous layer

- Further layers are fused

- The process continues until the model is complete

5. Metal Extrusion

Material extrusion is one of the most simple additive manufacturing technologies to understand. Material is drawn through a nozzle, heated, and deposited onto the platform layer by layer. The nozzle moves horizontally while the platform moves up and down as each layer is deposited.

A step-by-step look at the material extrusion process:

- The nozzle deposits material on the platform, creating the first layer

- The next layer is added on top of the previous layer and continues until the object is complete

- Layers are then fused together

6. Vat Photopolymerization

The vat photopolymerization process uses a tub of photopolymer resin to build its objects layer by layer. Afterward, an ultraviolet (UV) light hardens the resin where necessary.

Unlike powder-based methods, no structural support is made from the material to stabilize the object being made. The operator must add support structures manually.

Here is a simplified look at vat photopolymerization:

- The platform is lowered from the resin vat

- A UV light hardens the resin while the platform continues to move down and adds layers

- Upon completion, the vat is drained and the object is removed

7. Sheet Lamination

The sheet lamination process includes two types of manufacturing: ultrasonic additive manufacturing (UAM) and laminated object manufacturing (LOM).

UAM uses sheets of metal that are bound together using ultrasonic welding. LOM uses a similar layer-by-layer tactic but instead uses paper as the primary material and adhesive instead of metal and welding, respectively.

The sheet lamination process is as follows:

- The material is placed on the cutting bed

- The material is locked in place using adhesive

- The desired shape is cut from the layer using a laser or knife

- Another layer is added

- Repeat the third step

- Repeat the second step

8. Directed Energy Deposition

Directed energy deposition, or DED, is a much more complex process, typically used to repair or add onto an existing component. It spans several different manufacturing processes and typically costs more than other additive manufacturing types.

Here’s a simplified look at the directed energy deposition process:

- An arm with 4-5 axis points moves a nozzle around a fixed object

- Material is pushed through the nozzle and added onto existing substrates

- The added material is melted using an electron beam, laser, or plasma arc upon deposition

- More material is added layer by layer as needed

Additive Manufacturing Materials

Engineers have the opportunity to use many different materials in the additive manufacturing process. With material flexibility, metal AM is expected to grow and innovate with future technology.

Materials suitable for the additive manufacturing process include:

- Metals

- Thermoplastics

- Ceramics

- Biochemicals

Metals

Metal is one of the most common (and useful) materials used in the additive manufacturing process. Although sometimes more costly than other materials, the durability, design capabilities, and quality are worth the investment.

Several different metals are viable in additive manufacturing, including:

- Steel

- Stainless steel

- Titanium

- Gold

- Silver

Thermoplastics

Thermoplastics, also known as polymers, is another common material used in additive manufacturing. Polymers typically have high availability and lower costs but aren’t durable. Unlike metal used for large industries, polymers are commonly used by enthusiasts with at-home 3D printing capabilities.

The most popular thermoplastics in the additive manufacturing process are:

- Polylactic acid (PLA)

- Polycarbonate

- Polyvinyl alcohol (PVA)

- Acrylonitrile butadiene styrene (ABS)

Ceramics

Ceramics are a newer material used in additive manufacturing and 3D printing. They have several advantages over both metals and thermoplastics due to their ability to withstand immense heat and pressure without breaking or warping.

Ceramic additive components also feature the following advantages and characteristics:

- Resistance to heat, pressure, acid, and lye

- Wide range of color options

- Smooth and glossy surfaces

Biochemicals

Biochemicals are a commonly used material for additive manufacturing in the healthcare industry and a wide variety of other applications. The most popular biochemicals in the additive manufacturing process include:

- Calcium phosphate

- Zinc

- Silicon

Metal Additive Manufacturing Applications

Metal AM is used for a variety of applications, some of the most important include:

- Producing models and prototypes during a project’s development phase

- Conducting short-series production that would be far more expensive using casting or injection molding (tooling costs drop significantly)

- Producing pilot-series parts in the automotive, medical, and aerospace industries

- Creating parts with immense geometrical complexity that’s impossible via traditional molding, milling, grinding, casting, etc.

Advantages of Additive Manufacturing

Additive manufacturing component production comes equipped with several advantages over traditional manufacturing processes:

- Shape complexity

- Weight reduction

- Time-saving through increased efficiency

Complex Components

With traditional metal forming processes, creating complex components typically comes with a long wait time, high prices, and custom tooling creation. However, in additive manufacturing, complex components are rather simple to create.

Think of a design with multiple movable parts and a hollow inside. With traditional manufacturing, engineers need to hollow out the components while ensuring that the parts can move together. But with additive manufacturing, it’s as simple as not adding material to the middle.

Since components are made layer by layer with additive manufacturing, engineers can simply skip filling the middle and focus more on the mobility of the connected parts. Not only does this reduce the chance of errors in your component; but it also saves you money and time.

Produce Lightweight Parts

Reducing product weight can deliver significant savings in materials, costs, and lead times. Just look at GE Aviation: This manufacturing giant says that reducing just 1 lb. on a Boeing 737 design reduces annual operating costs by hundreds of thousands of dollars.

With additive manufacturing, you have the ability to produce lightweight parts that don’t compromise the integrity of the finished product. This also means you can order thousands of the same part without worrying about the price of shipping going up dramatically.

Time-Saving Through Efficiency

Today’s tech world is fast-paced, and demands for better material solutions drive the need for tighter turnaround times in the manufacturing industry. Luckily, additive manufacturing is a step ahead of the game.

With additive manufacturing, you can save time and money by saving material. No secondary operations are necessary to remove excess material from a component. The only material that will need removed post-production is any temporary structural support.

Additive manufacturing is capable of handling low-volume orders as well as mass production, making it a versatile and valuable process for companies of all sizes and specialties.

Discover the Potential of Metal AM

Additive manufacturing is constantly evolving to keep up with current technology. Understanding the basics of the process and its potential is essential to stay up to date with manufacturing trends.

Hopefully, this overview has given you baseline knowledge to answer your burning question, “What is additive manufacturing?” As this advanced technology continues to evolve and adapt to market demands, the answer to this question will also evolve.

Editor's Note: This blog was originally published on Oct 27, 2021 and was updated in August 2023