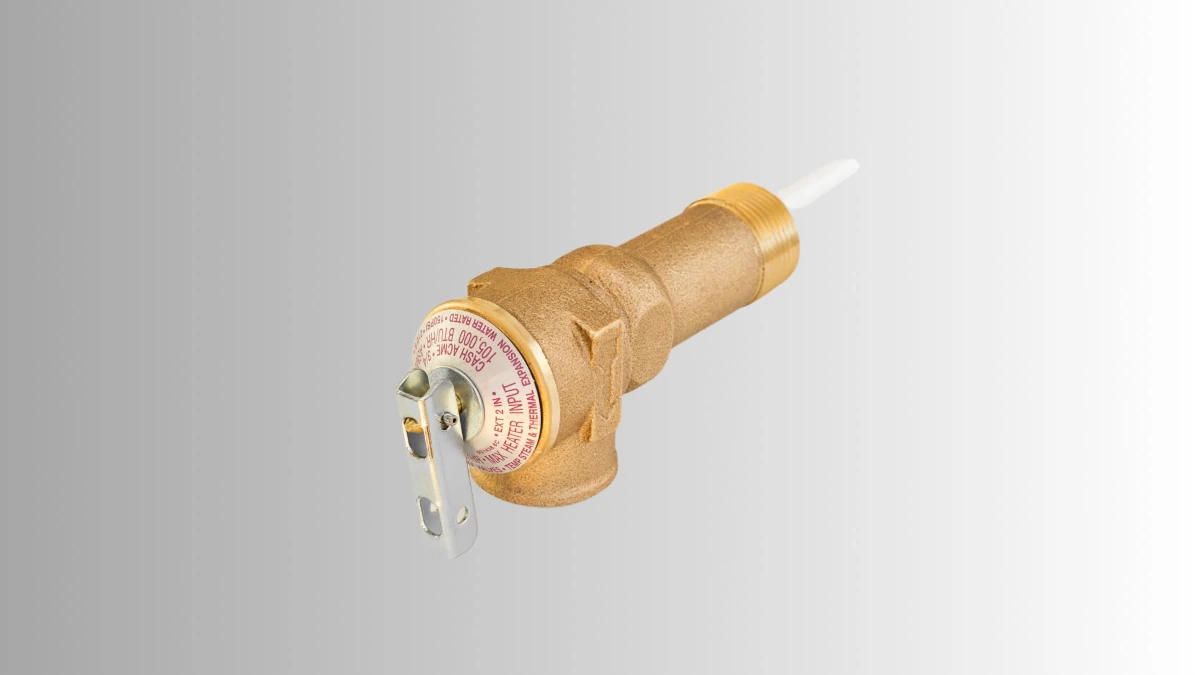

What is a Pressure Relief Valve?

|

Ever seen someone pop the cork off a champagne bottle? That fizzy explosion is a result of the pressurized carbon dioxide. In the engineering world, when pressure builds, pressure relief valves (PRV) serve a similar purpose – albeit with a touch more sophistication. They may not be the toast of every party, but when it comes to safety, PRVs are the real MVPs. Let’s take a closer look at what a pressure relief valve really is and what purpose it serves: Defining the Purpose of Pressure Relief ValvesPressure relief valves play a role that’s both subtle and crucial. PRVs silently and diligently monitor and manage pressure, ensuring harmony in the systems they oversee. Let’s examine their purpose in the grander scheme of things: 1. Safety:PRVs are designed to protect equipment, the environment, and people. Their primary role is to ensure equipment, such as boilers, pipelines, and tanks, operate within their pressure limits. This not only prolongs the life of equipment but also reduces the risk of catastrophic failures. 2. Operational Integrity:

|

| HVAC Systems: Pressure relief valves are critical components in HVAC (Heating, Ventilation, and Air Conditioning) systems. They help regulate and control the pressure within HVAC equipment such as chillers, boilers, and piping systems. These valves ensure that pressure remains within safe operating limits, preventing system damage and maintaining efficient operation. |

| Steam Boilers: Pressure relief valves are crucial in steam boiler systems to prevent excessive pressure buildup that can lead to explosions or equipment failure. |

| Fuel Tanks: Pressure relief valves are commonly used in fuel storage tanks to prevent tank rupture or damage caused by pressure fluctuations, ensuring the integrity and safety of the fuel storage system. |

| Piping Systems: PRVs are installed in piping systems to safeguard against pressure surges or blockages. |

| Hydraulic Systems: Pressure relief valves ensure the safe and controlled operation of hydraulic cylinders, pumps, and other components by releasing excessive fluid pressure. |

| Compressed Air Systems: PRVs are used in compressed air systems to prevent the buildup of excessive pressure that can lead to damaged equipment or leaks. |

| Chemical Processing: PRVs are essential in chemical processing plants to protect vessels, reactors, and pipelines from overpressure situations caused by chemical reactions or process upsets. |

| Refining Industry: Pressure relief valves are commonly used in refining operations to protect equipment such as distillation columns, heat exchangers, and storage tanks. |

| Water Supply Systems: PRVs are used in water supply systems to regulate and maintain optimal water pressure, protect pipes and fixtures from damage due to excessive pressure, and help prevent bursts or leaks. |

| Refrigeration Systems: Pressure relief valves are used to protect against overpressure situations that can occur due to factors such as temperature fluctuations or system malfunctions. |

PRVs: Thriving Under Pressure

As we navigate the complexities of a world constantly under pressure, pressure relief valves serve as silent heroes, providing the peace of mind that comes with knowing that our processes, machinery, and personnel are protected. Whether it’s protecting against catastrophic explosions or safeguarding equipment from damage, pressure relief valves play a crucial role in maintaining the integrity and safety of various systems.

Have questions? Reach out to one of our experts today!