Die Casting vs. Metal Injection Molding: An In-Depth Analysis

Whether you’re producing small, intricate parts or large, simple components, there are several manufacturing methods to choose from. The method you choose may come down to comparing factors such as raw material use, product design, costs and what material is required for the applications.

There are two methods most prominently used – die casting and metal injection molding. These methods suit most customers across a variety of industries and typically can’t replace each other, but it’s still essential to understand the ins & outs of each process.

In this blog, we’ll review the basics of each process, common applications of die casting and MIM, and compare the two processes in-depth.

What is Metal Injection Molding?

Metal injection molding uses traditional injection molding equipment to create small and intricate metal parts. These manufactured parts possess relatively high strength, durability, and good wear characteristics. Manufacturers may recommend MIM when geometry requires thin walls, which is a common customer request.

In addition to choosing MIM because of geometry, volume, and tolerance requirements, customers select metal injection molding due to cost considerations. The process lowers costs in three ways:

- The process repeatedly produces quality batch parts

- Manufacturers experience less waste with MIM

- Parts tend to be near net shape and require minimal secondary processing or machining

Metal Injection Molding Process

The metal injection molding process starts with a material known as the feedstock. Feedstocks are compounded by combining powder metal material and a binder system. This binder is used as a carrying agent to transfer the powder metal into a custom-designed mold. The motion is controlled by heat and pressure, which melts the binder and is pushed by a hot screw into the mold. Once this is complete, the molded part cools and is removed from the mold by an ejection process.

The next step is to remove that binder material that was only utilized to carry the powder metal into the mold. The removal process consists of either a thermal, catalytic, or solvent process depending on the binder system selected.

This part then goes through a sintering process, done in a batch or continuous belt furnace. The objective of sintering is to consolidate and mechanically bond the individual particles of powder metal. In this step, the part reaches a very high density which results in typical mechanical and chemical properties based on the alloy system utilized.

Resource: To get more information on metal injection molding, download our in-depth guide on the process.

Common Metal Injection Molding Applications

Since metal injection molding excels at creating complex, intricate, and small parts with tight tolerances and thin walls, it’s commonly found in several applications including:

- Firearms: fire control group components, sights, bolts, ejectors

- Medical: joint replacement parts, surgical instruments, drug delivery systems

- Automotive: electrical connectors, system controllers, shift levers

- Industrial: drone parts, micro gears, machinery components

- Aerospace: engine components, flap screws, valve holders

- Electronics: mobile phone componentry, smart wear, cable accessories

What is Die Casting?

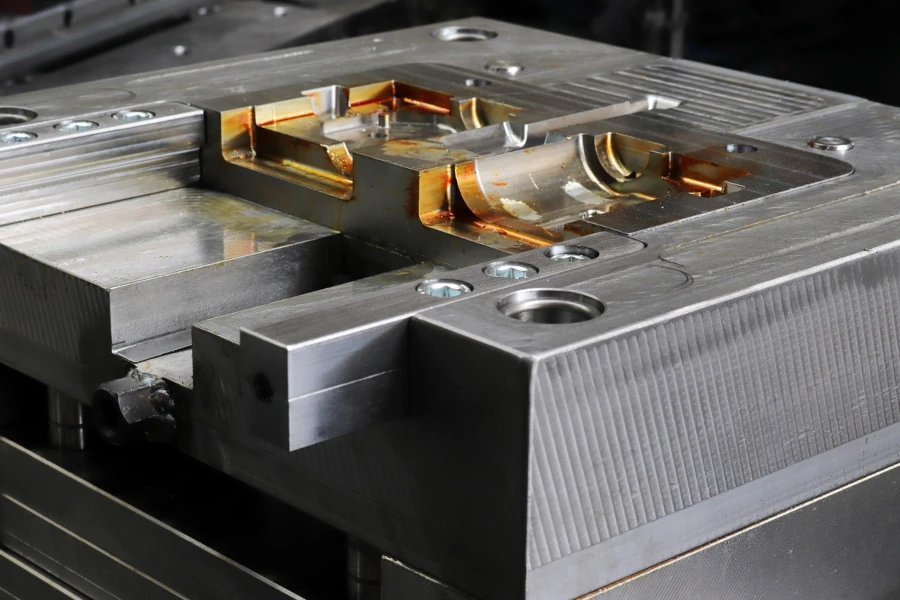

Die casting manufacturing processes involve taking non-ferrous molten metals and forming them into parts using dies. There are numerous die parts that may be used that can form various shapes and internal components. These dies consist of single-cavity dies that make a single part, combination dies that make several different parts at once for a single assembly, unit dies that use one cast cycle to make several different parts, and multiple-cavity dies that provide several parts that are identical.

Customers may select this process because it’s simple. Die casting can mass produce highly durable and complex parts, while still retaining original specifications, allowing for the exact duplication of parts.

Die Casting Process

During the die casting process, a clean die is clamped shut and lubricated to control internal temperatures as molten metal is injected into the die using high pressures. The part is allowed to cool as it is then ejected from the die.

There are typically three die casting processes: gravity die casting, cold die casting, and hot die casting.

- Gravity die casting uses gravity to move the molten metal into the mold.

- Cold die casting requires workers to ladle the molten metal into the machine that injects the molten metal at high pressures.

- Hot die casting has a furnace that feeds the molten metal directly into the injection machine using a gooseneck.

Common Die Casting Applications

Die casting is extremely versatile, allowing it to be used for customers in a vast variety of industries. A few of these industries include the following:

- Firearms: triggers, trigger guards, safeties

- Medical: surgical devices, peristaltic pumps, blood analysis machines

- Automotive: gear housings, powertrain systems, engine components

- Industrial: outboard gear case, hydrostatic axles, steel liner inserts

- Electronics: electrical housings, antenna mounts, RF filters

Metal Injection Molding vs. Die Casting

When comparing die casting processes to metal injection molding, there are five key differences that may impact which method is better for your project.

- Precision & tolerances

- Materials used

- Surface finish

- Tooling/manufacturing costs

- Mold differences

1. Precision & Tolerances

Metal injection molding creates very precise parts with relatively tight tolerances. On the other hand, die casting can have varying dimensions which usually require the part to be trimmed to meet specifications. Also, die casting does not allow much control over wall thickness.

2. Materials Used

MIM allows for both non-ferrous and ferrous materials. Die casting typically uses non-ferrous metals. The difference is ferrous metals contain iron while non-ferrous metals don’t.

3. Surface Finish

Die casting may require excess metal to be trimmed off and offers a medium surface finish. MIM allows for a high surface finish that typically doesn't require additional finishing.

4. Tooling/Manufacturing Costs

Costs are dependent on the complexity of the part. While metal injection molding offers low costs, it does have higher process costs than die casting. Die casting may be cheaper than MIM, depending on the specific application.

5. Mold Differences

MIM allows for greater flexibility when it comes to the mold, yet the mold might have a reduced lifespan. Die casting has good flexibility, yet not as much as MIM methods. Dies used in die casting, however, typically last longer.

Choosing a Manufacturing Method

Ultimately, when choosing a manufacturing method, you have to take your design, desired materials, and the end use of the part you’ll be manufacturing into consideration.

If you’re looking to learn more about metal injection molding and die casting, reach out to our team of experts at APG to get started on your next project.