The Impact of Medical Additive Manufacturing on the Healthcare Industry

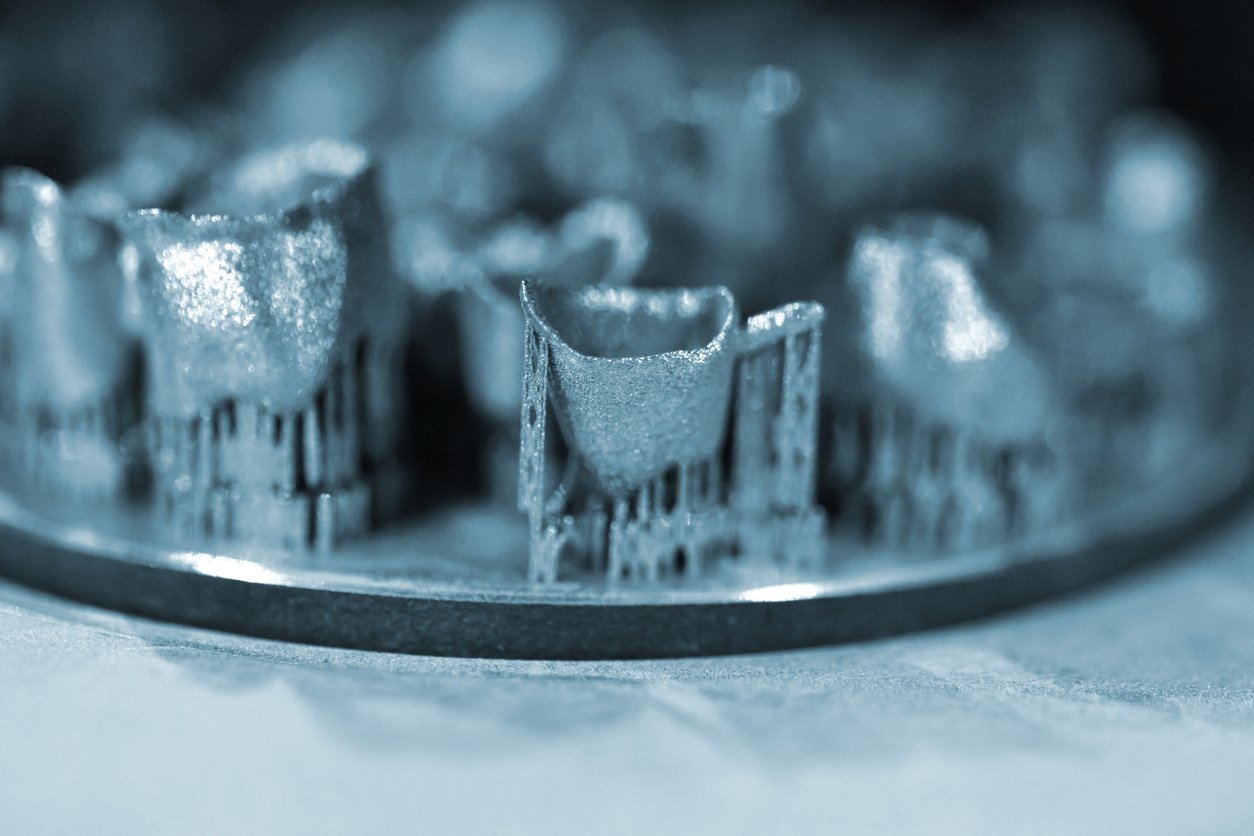

Metal additive manufacturing, also known as metal 3D printing or metal AM, is revolutionizing the healthcare industry by offering unmatched precision, customization, and efficiency. Metal AM enables the creation of complex medical devices, implants, and tools that were previously unimaginable.

Below, we explore the key benefits of metal additive manufacturing in healthcare, highlighting how this technology is transforming patient care and medical engineering.

Eight Key Benefits of Medical Additive Manufacturing

Metal AM is changing the medical manufacturing landscape in the following ways:

1. Personalized Medical Devices and Implants

At the heart of metal additive manufacturing is its ability to produce medical solutions tailored to the unique anatomical requirements of individual patients, ensuring an optimal fit and significantly improved functionality. This customization extends from patient-specific designs, where devices and implants are created using detailed 3D scans of a patient's anatomy, to enhanced comfort and recovery, where custom-fit implants and prosthetics significantly improve the recovery journey and patient satisfaction.

2. Unmatched Precision and Performance

Metal AM facilitates the creation of medical devices and components with intricate designs and superior material properties. This includes achieving complex geometries with high precision and superior material properties, critical in medical applications where there is no room for error. The layer-by-layer construction process allows for the creation of features with tight tolerances and complex internal structures, enabling devices to perform highly specific functions within the human body.

3. Rapid Prototyping and Production: Speeding Up Innovation

Metal additive manufacturing significantly reduces the development time of medical devices, enabling rapid prototyping and testing. This quick turnaround from design to production, coupled with on-demand manufacturing, reduces inventory costs and waste, accelerating the pace of innovation in the healthcare sector.

4. Advanced Material Utilization: Biocompatible and Durable Options

The use of biocompatible materials like titanium and its alloys, known for their strength, lightweight properties, and compatibility with the human body, is a key advantage of metal AM. These materials ensure the durability and longevity of medical devices and implants, which is critical for permanent implants.

5. Cost-Effectiveness in Production: Reducing Waste and Lowering Costs

Metal additive manufacturing minimizes material waste by using only the necessary amount of material to build a part, unlike subtractive methods. This material efficiency, combined with the reduced cost of producing custom or low-volume parts, makes advanced medical solutions more accessible.

6. Enhanced Surgical Planning and Tools: Improving Surgical Outcomes

Surgeons can use 3D-printed models of patient anatomy for pre-surgical planning, improving the understanding of complex cases. Additionally, the creation of bespoke surgical tools designed for specific procedures or patient anatomies enhances surgical precision and reduces operation times.

7. Innovation in Orthopedic and Dental Implants: Pioneering New Treatments

Metal AM is pioneering new treatments in orthopedic and dental implants, creating porous surfaces that encourage bone growth and improve the stability of these implants. This leads to implants that are more resilient and compatible with patients' bodies, improving long-term outcomes.

8. Facilitating Research and Development: Accelerating Medical Advances

The flexibility of metal additive manufacturing fosters collaboration between engineers, medical professionals, and researchers, leading to breakthroughs in medical science. Researchers can quickly prototype and test new medical device designs, materials, and structures, speeding up the innovation process.

Paving the Way for the Future for Metal AM in Healthcare

Metal additive manufacturing is setting a new standard in the healthcare industry, offering benefits that extend from the manufacturing floor to the operating room and beyond. By harnessing the power of this technology, the healthcare sector can look forward to advancements that promise not only to enhance patient care but also to usher in a new era of medical treatment where the limitations of traditional manufacturing are a thing of the past.

As we continue to explore the potential of metal additive manufacturing, its role in shaping the future of healthcare becomes increasingly significant, promising a world of medical solutions that are more personalized, efficient, and accessible.

Want to learn more about metal additive manufacturing? Check out our blog or reach out to one of our experts!