Metal Hybrid Additive Manufacturing - What it is, Use Cases, & More

Metal hybrid additive manufacturing (MHAM) is a fairly new technology that is quickly gaining popularity. In this blog post, we will discuss what metal hybrid additive manufacturing is and some of its potential uses.

What is Metal Hybrid Additive Manufacturing?

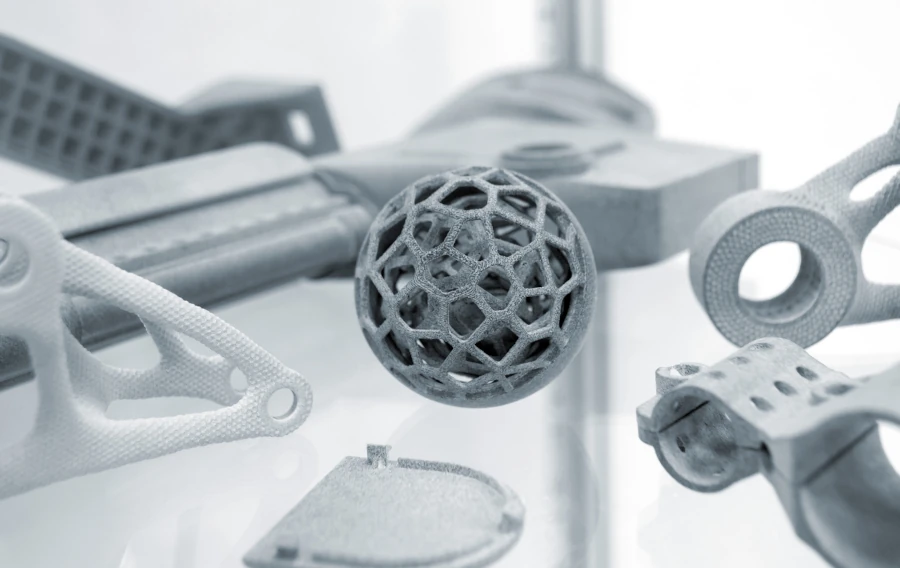

Metal hybrid additive manufacturing is a process that combines traditional subtractive manufacturing methods, such as machining and milling, with additive manufacturing methods, such as 3D printing. This allows for the creation of complex parts and products with less waste. MHAM can be used for a variety of applications, including prototyping, tooling, and end-use parts.

A Combination of Additive & Subtractive Processes

In traditional subtractive manufacturing, a piece of metal is machined or milled into the desired shape. In additive manufacturing, a three-dimensional printer builds up the desired object, layer by layer, from a digital model.

Metal hybrid additive manufacturing combines these two processes to create parts and products that would be impossible to create with either method alone. For example, metal hybrid additive manufacturing can be used to create complex internal features, such as cooling channels, that would be difficult or impossible to create with traditional methods.

Metal Hybrid Additive Manufacturing Use Cases

Metal hybrid additive manufacturing is a relatively new technology, but it's already being used in a variety of industries. Some of the most promising applications for this technology include aerospace, medical devices, and automotive.

Aerospace

Metal hybrid additive manufacturing is well suited for the aerospace industry due to the need for light-weight parts with complex geometries. This technology can be used to create parts for aircraft and satellites that are lighter and stronger than those made with traditional methods.

Medical Devices

Metal hybrid additive manufacturing is also being used to create medical devices, such as implants and prosthetics. This technology can be used to create custom-fit devices that are less likely to cause complications.

Automotive

Metal hybrid additive manufacturing is also being used in the automotive industry to create prototypes and production parts. This technology offers the potential to create lighter, stronger parts with complex geometries. With the amount of components on an automobile, cutting a fraction of the tooling costs out makes a huge impact on the total cost of ownership, which can be felt by the manufacturer and the consumer.

Metal Manufacturing For the Future

Metal hybrid additive manufacturing is a versatile technology with a wide range of potential applications. This technology is sure to have a major impact in a variety of industries in the years to come. Ready to learn more about additive manufacturing? - check out our blog.